How To Maintain Model 40B Numbering & Lettering Press

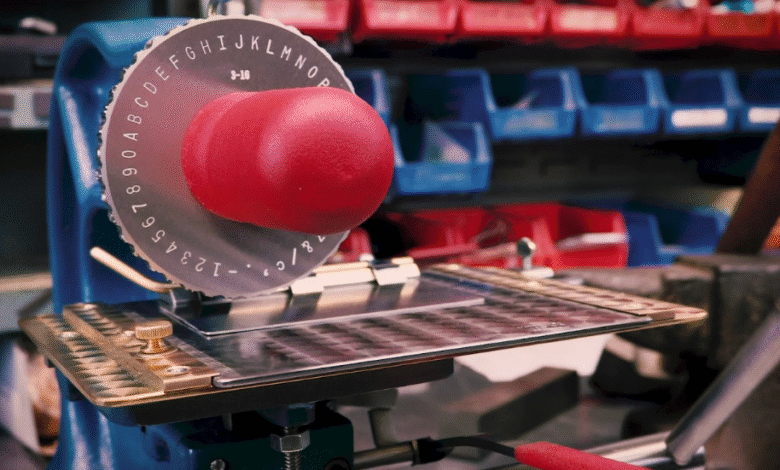

Have you ever wondered where those numbers and names on your dog collar, housebell, or letterbox come from? If you are new to it, let me introduce you to the Model 40B Numbering & Lettering Press. This creative and productive machine is responsible for writing letters and names on almost anything you see. If you’ve been in business requiring lettering names on keys or other objects, you already know how this machine is used. However, owning and using the machine is not enough. You should know how to maintain it for years to come. In high-demand industrial environments where accuracy and consistency are non-negotiable, regular maintenance of your 40B press is important.

In this blog, we’ll walk you through the key steps and best practices to keep your Model 40B operating smoothly and precisely for years to come.

Keep Your Model 40B Numbering & Lettering Press Clean

Metal shavings, dust, ink residue, and general grime can quickly accumulate in and around the press, mainly when operating at high volume. Moreover, this buildup not only reduces the efficiency of the media but can also lead to wear and tear over time.

Daily Cleaning Tips:

- Use a soft brush or compressed air to remove loose debris.

- Wipe down the metal parts with a lint-free cloth.

- Avoid using water or corrosive cleaning agents; opt for a mild solvent or machine-safe cleaner if needed.

Pro Tip: Clean the character wheels thoroughly at the end of each shift to prevent clogging or misprints.

Lubricate Moving Parts Regularly

The Model 40B Numbering & Lettering Press contains several moving parts, including levers, gears, and stamping heads. Over time, friction can cause these parts to wear down or stick, leading to inconsistent impressions or mechanical failure.

Lubrication Guidelines:

Use high-quality machine oil specifically recommended for metal presses.

Focus on pivot points, joints, and gear tracks.

Lubricate every 1-2 weeks, or more often in high-use environments.

Warning: Avoid over-lubricating, as it can attract dust and gum up the machine.

Check Alignment and Calibration

Even a slight misalignment in the Model 40B Numbering & Lettering Press can result in crooked, uneven, or incomplete impressions. On the other hand, this is especially important when you’re producing tags that must meet industry compliance standards.

How to Stay Aligned:

- Periodically check that the character wheels are appropriately seated and spinning smoothly

- Use a test metal blank to guarantee that impressions are centered and clear.

- Recalibrate the depth and spacing settings as needed, particularly after moving or transporting the machine.

Inspect for Wear and Tear

Routine inspections help identify possible issues before they become costly problems. Focus on the condition of the dies, stamps, and any replaceable components.

What to Look For:

- Worn or faded typefaces on character wheels.

- Loosened fasteners or bolts.

- Cracks, dents, or corrosion in the press body.

- Replace any worn components immediately to maintain stamping quality and protect the rest of the machine.

See also: Exploring Tech Innovations in the Automotive Industry

Store and Handle with Care

While the Model 40B Numbering & Lettering Press is built for tough environments, proper storage and handling can significantly extend its lifespan.

Best Practices:

- Cover the machine when not in use to protect it from dust and moisture.

- Always use the handle and transport aids to move the press; never drag or lift by delicate components.

- Keep it in a dry, temperature-controlled workspace to avoid rust and oxidation.

Schedule Preventive Maintenance

Don’t wait until something breaks. Create a preventive maintenance calendar that includes:

- Monthly deep cleaning and inspection.

- Quarterly calibration checks.

- Annual professional servicing, if available from the manufacturer or authorized service providers.

- Logging this maintenance also helps build a track record for machine condition, useful when planning future upgrades or audits.

Conclusion

The Model 40B Numbering & Lettering Press is an industrial workhorse, but like all machines, it needs consistent care to keep it running at its best. Regular cleaning, lubrication, alignment, and inspections go a long way in guaranteeing that your press delivers sharp, accurate tags day after day. Investing just a little time in maintenance today can prevent downtime, costly repairs, and operational headaches tomorrow. Additionally, a well-maintained Model 40B not only guarantees productivity but also maintains the high standards your industry demands.

Need help sourcing maintenance kits or spare parts? Reach out to your professional supplier, like Short Order Product or the manufacturer, for the recommended accessories to keep your press in peak condition.